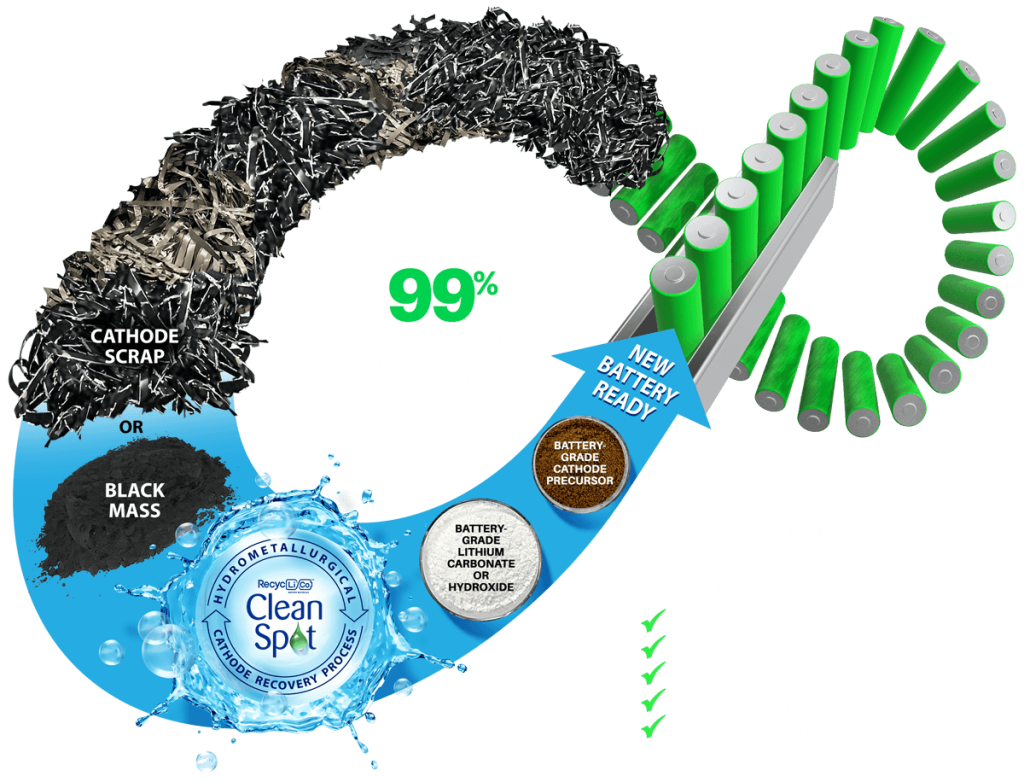

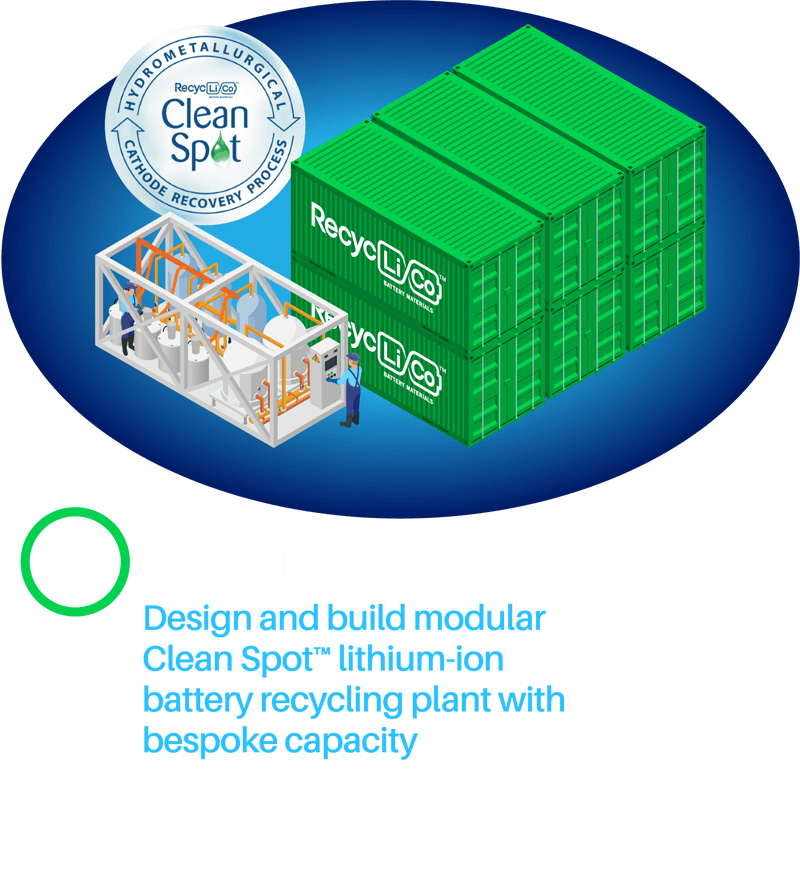

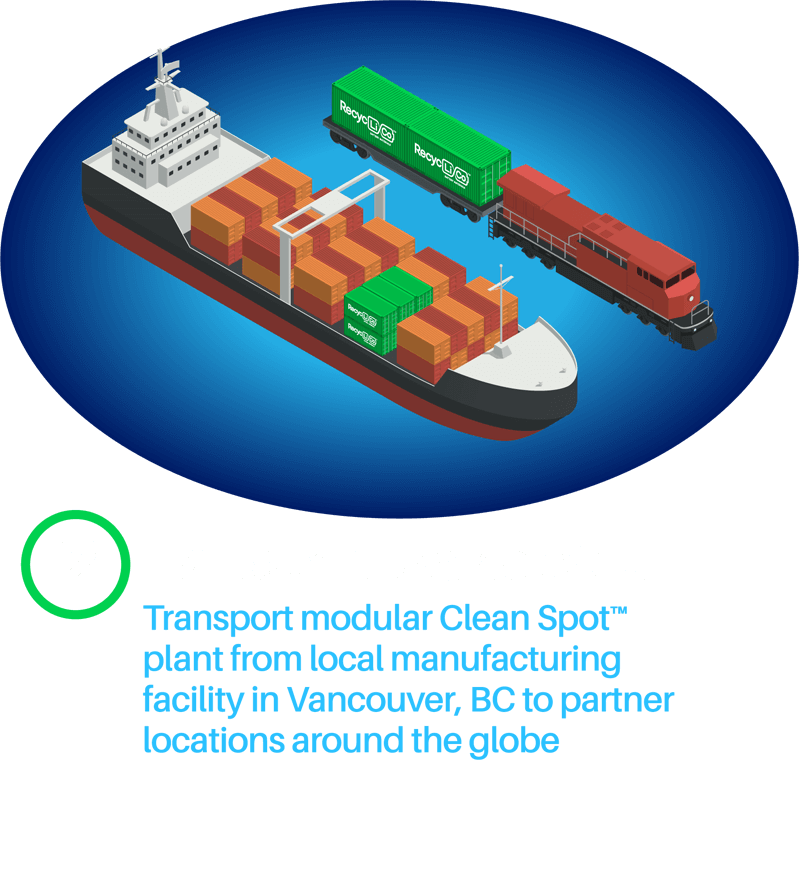

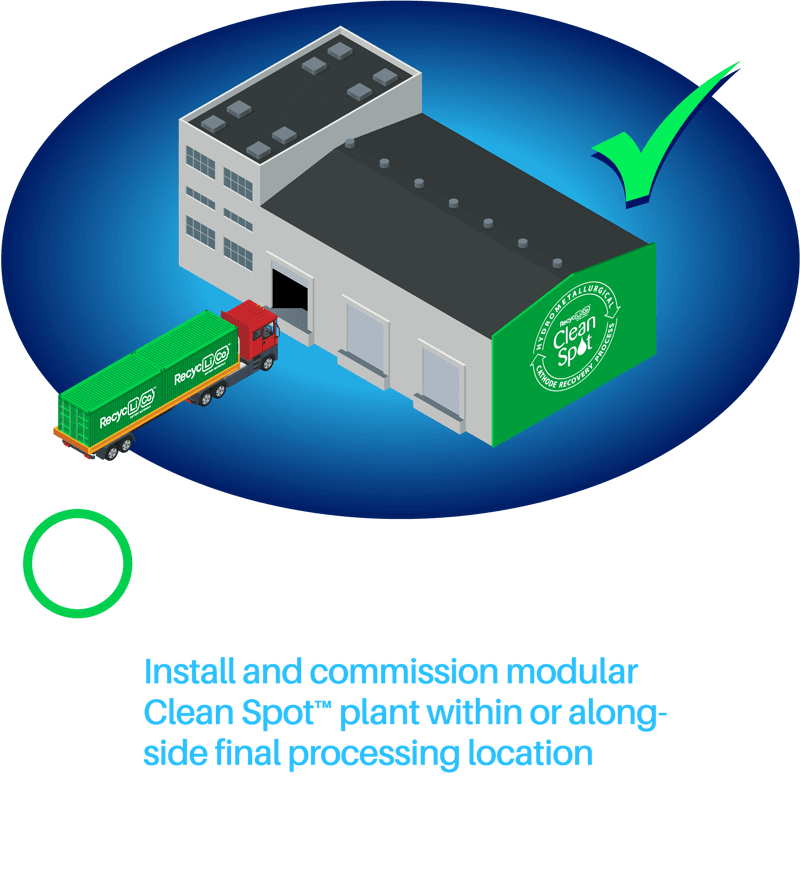

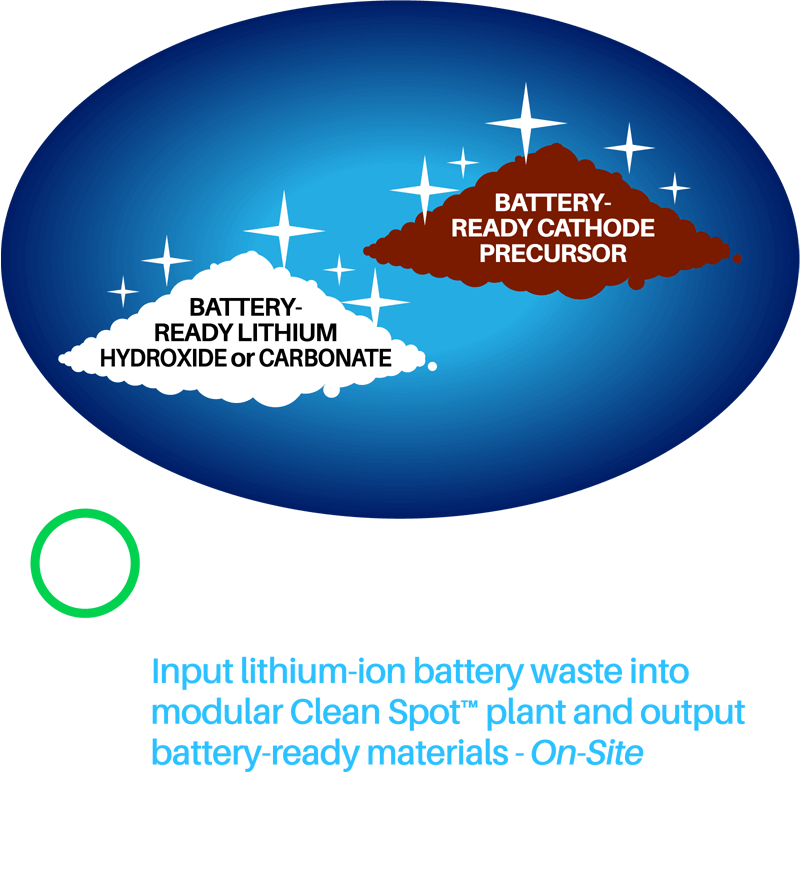

RecycLiCo recovers up to 99% of cathode metals from battery waste and upcycles them into high purity, battery-ready materials.

RecycLiCo recovers up to 99% of cathode metals from battery waste and upcycles them into high purity, battery-ready materials.