LCA was Conducted in Accordance with ISO Standards and Critically Reviewed by Independent Experts

RecycLiCo Battery Materials (“Company“), is pleased to announce the results of a life cycle assessment (LCA) completed by Minviro Ltd. (“Minviro”), a UK-based and globally recognized sustainability and life cycle assessment consultancy, on the Company’s lithium-ion battery recycling-upcycling process.

An LCA is a standardized, scientific method for quantifying the direct and embodied environmental impacts associated with a particular product or process. By considering all material and energy inputs such as scope 1, 2 and 3 CO2 emissions. The LCA was conducted in accordance with ISO-14040:2006 and ISO-14044:2006 standards and a critical review was conducted on the LCA by independent experts. The LCA was carried out with a combination of data provided by RecycLiCo and public databases.

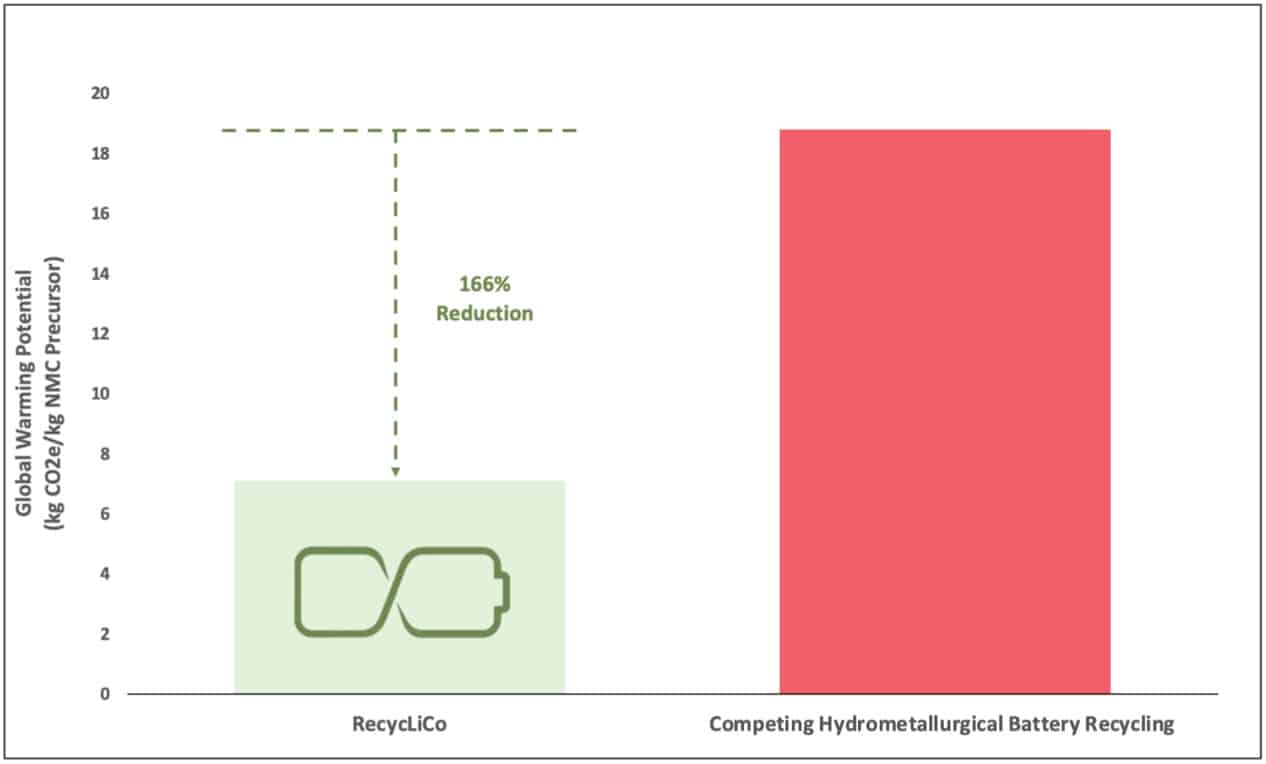

The report assesses the Company’s process against competing hydrometallurgical recycling methods, on the basis of producing one kilogram of NMC precursor material, as follows:

“Global Warming Potential” refers to the potential CO2 equivalent emissions made by a particular recycling method, in producing one kilogram of NMC precursor material. As shown in the table, competing hydrometallurgical recycling methods will likely produce 166% more CO2 equivalent emissions when compared to the RecycLiCo process. To put this into context, such a variance is about the same as 17,000 tons of CO2 per GWh of NMC battery material recycled, which is roughly equivalent to the amount of emissions made by 3,700 vehicles in a year on average.1

“Global Warming Potential” refers to the potential CO2 equivalent emissions made by a particular recycling method, in producing one kilogram of NMC precursor material. As shown in the table, competing hydrometallurgical recycling methods will likely produce 166% more CO2 equivalent emissions when compared to the RecycLiCo process. To put this into context, such a variance is about the same as 17,000 tons of CO2 per GWh of NMC battery material recycled, which is roughly equivalent to the amount of emissions made by 3,700 vehicles in a year on average.1

Minviro also found that the RecycLiCo process, when compared against the industry average for primary extraction methods (i.e. mining), results in a 35% reduction in CO2 equivalent emissions for NMC precursor production and a 74% reduction for lithium hydroxide production.

“I am pleased to report that the LCA results confirm RecycLiCo’s lower environmental impact to produce NMC precursor and lithium hydroxide, when compared to primary raw material extraction methods or competing hydrometallurgical recycling,” said Larry Reaugh, the Company’s President and CEO. “To collectively achieve true decarbonization as an industry, we must not cut corners at any stage of the lithium-ion battery supply chain and should instead recognize the most efficient and environmentally friendly technologies as an industry benchmark.”

About Minviro

Minviro is a London-based and globally recognized consultancy and technology company specializing in carrying out life cycle assessments in the technology metal space. The company provides quantitative environmental and climate impact data for mineral resource projects, battery manufacturers and OEMs to make environmentally informed decisions (www.minviro.com).

About RecycLiCo Battery Materials

RecycLiCo Battery Materials Inc. is a critical metals company focused on recycling and upcycling lithium-ion battery waste into high-value battery cathode materials, using its closed-loop RecycLiCo™ process. With minimal processing steps and over 99% extraction of lithium, cobalt, nickel, and manganese, the upcycling process creates valuable lithium-ion battery materials for direct integration into the re-manufacturing of new lithium-ion batteries.

1 Calculations are made by the Company and based on statistics found at https://www.epa.gov/greenvehicles/greenhouse-gas-emissions-typical-passenger-vehicle

On behalf of Management

RecycLiCo Battery Materials

Larry W. Reaugh

President and Chief Executive Officer

Share This Story, Choose Your Platform!

The Toronto Stock Exchange has not reviewed and does not accept responsibility for the adequacy or accuracy of this release. This news release may contain certain “Forward-Looking Statements” within the meaning of Section 21E of the United States Securities Exchange Act of 1934, as amended. All statements, other than statements of historical fact, included herein are forward-looking statements that involve various risks and uncertainties. There can be no assurance that such statements will prove to be accurate, and actual results and future events could differ materially from those anticipated in such statements. Important factors that could cause actual results to differ materially from the Company’s expectations are disclosed in the Company’s documents filed from time to time with the Toronto Stock Exchange, the British Columbia Securities Commission and the US Securities and Exchange Commission.