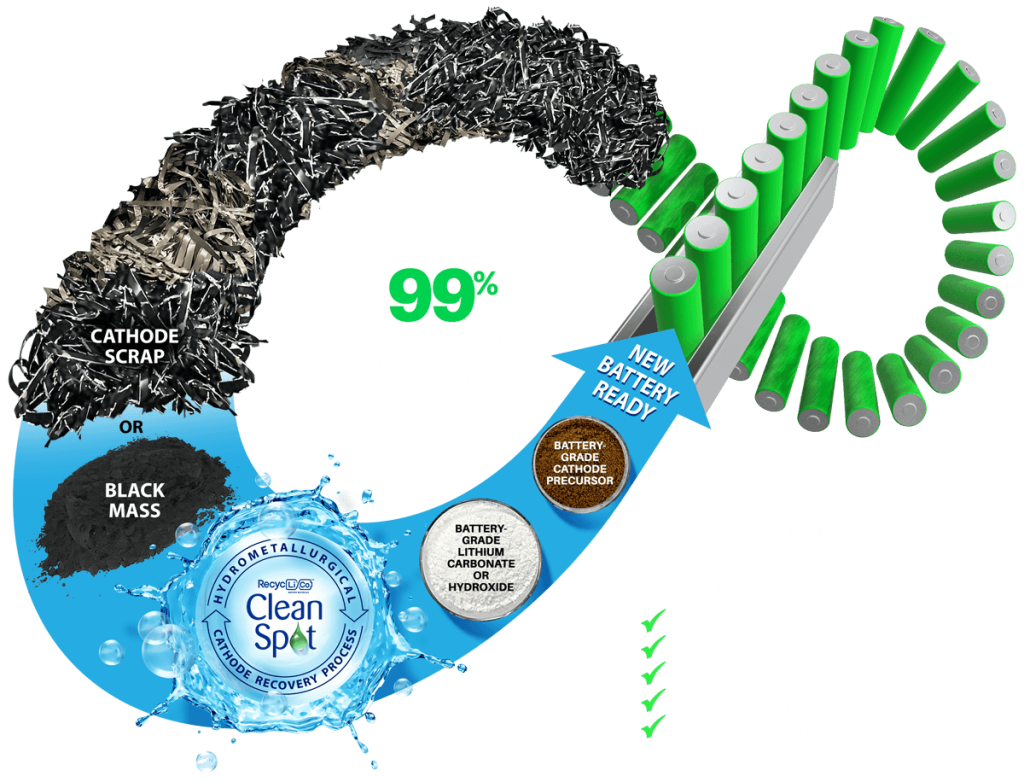

RecycLiCo Battery Materials recovers up to 99% of cathode metals from battery waste

and upcycles them into high purity, battery-ready materials.

Recover. Reuse. Repeat.

RecycLiCo Battery Materials recovers up to 99% of cathode metals from battery waste and upcycles them into high purity, battery-ready materials.

Recover. Reuse. Repeat.

Why ship your valuable battery waste outside your facility to a third-party recycler, only to buy back those recycled battery materials at multiples of its initial value?

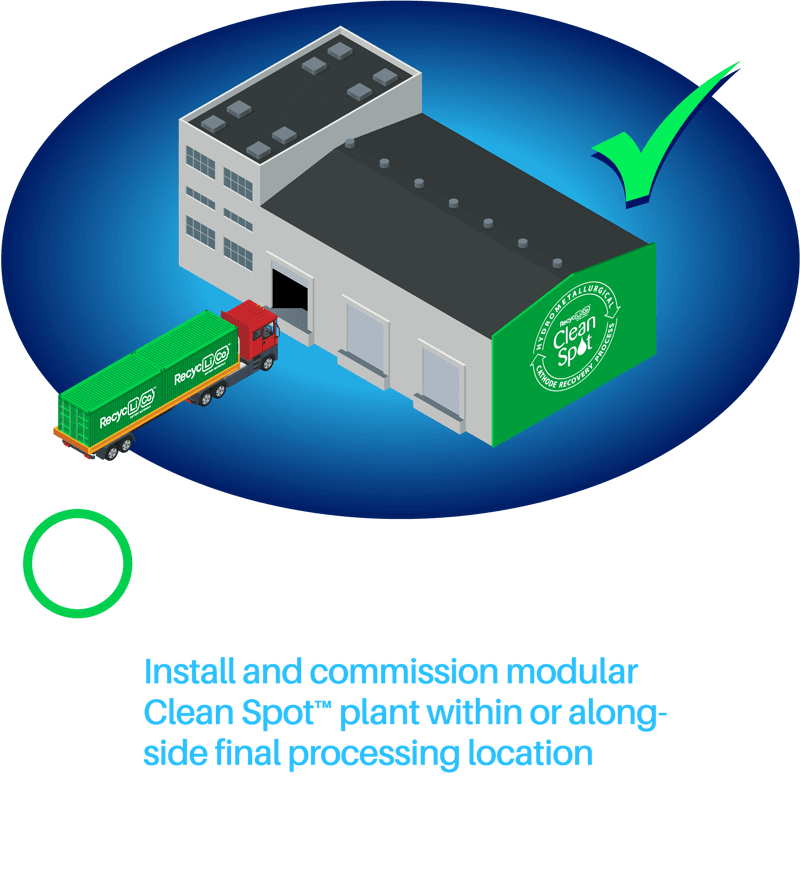

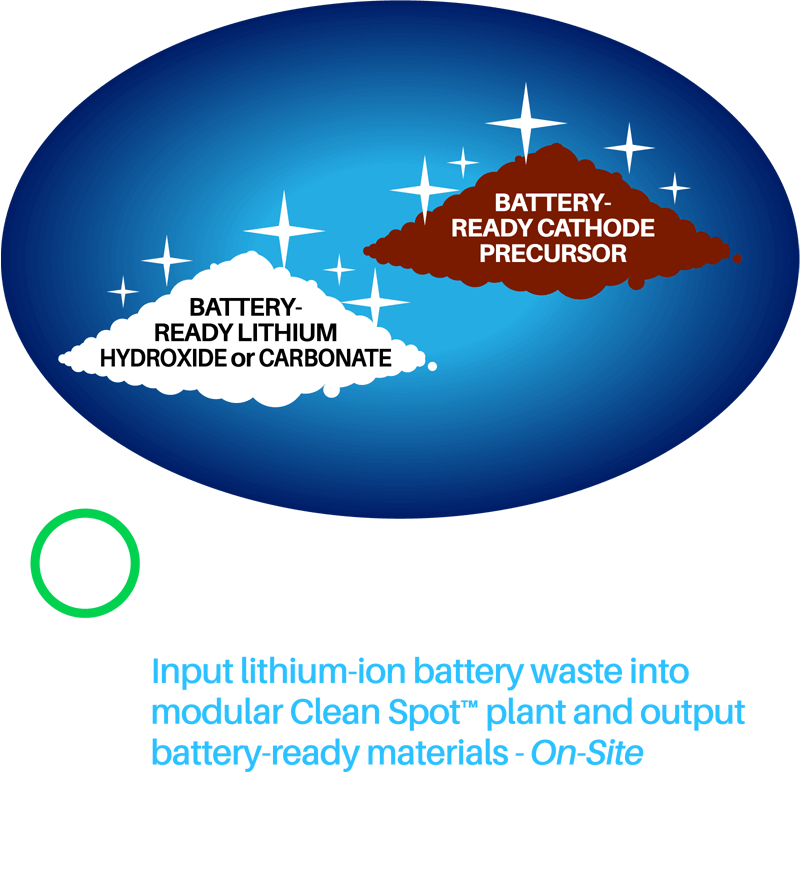

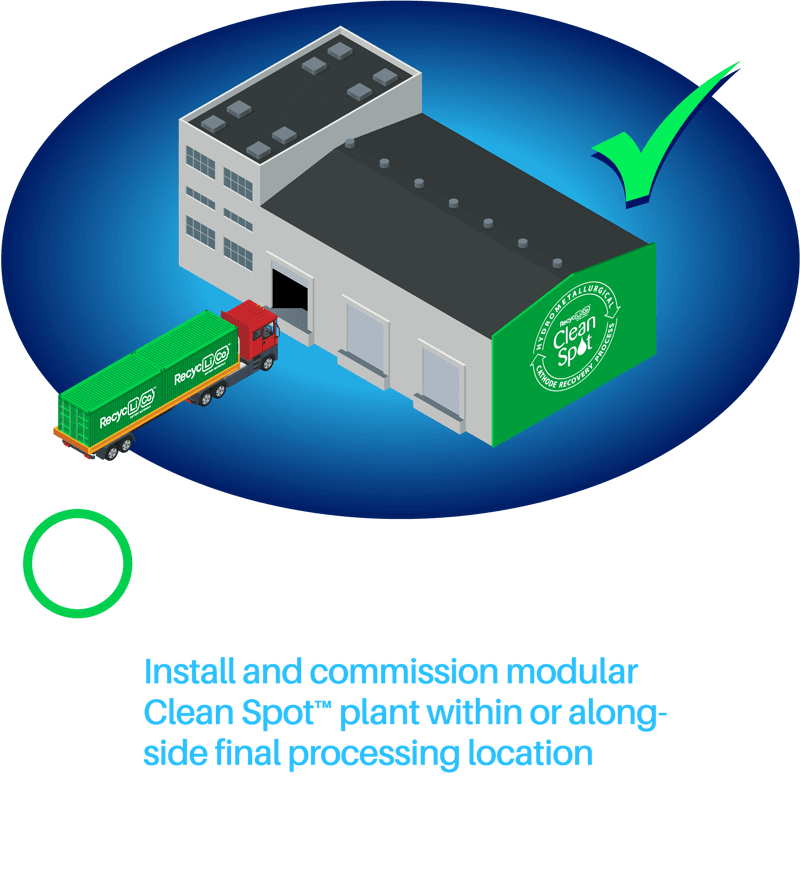

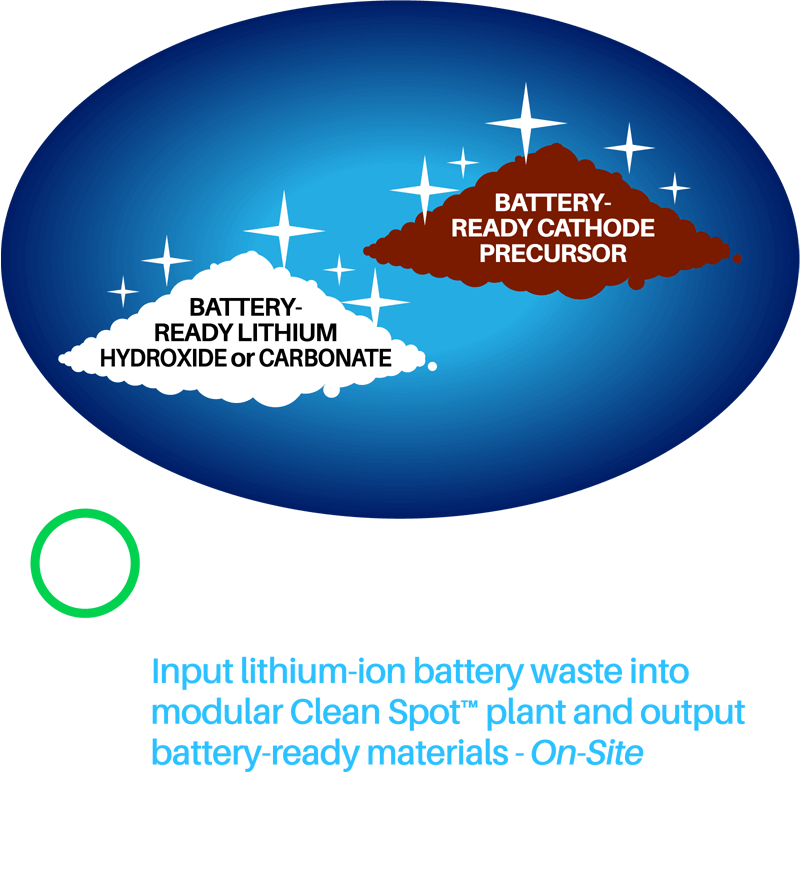

Integrate a bespoke RecycLiCo Clean Spot™ plant and its closed loop, multi-tonne per day, lithium-ion battery recycling and upcycling process – on-site – within your battery factory or battery recycling operation, and add the missing link to a truly green and efficient battery supply chain.

Recover up to 99% of your cathode materials and upcycle them into higher value, battery-ready materials which meet or exceed your high manufacturing standards for new battery production.

Why ship your valuable battery waste outside your facility to a third-party recycler, only to buy back those recycled battery materials at multiples of its initial value?

Integrate a bespoke RecycLiCo Clean Spot™ plant and its closed loop, multi-tonne per day, lithium-ion battery recycling and upcycling process – on-site – within your battery factory or battery recycling operation, and add the missing link to a truly green and efficient battery supply chain.

Recover up to 99% of your cathode materials and upcycle them into higher value, battery-ready materials which meet or exceed your high manufacturing standards for new battery production.

Making Battery Waste Battery-Ready

The Missing Link in a Truly Green and Efficient Battery Supply Chain

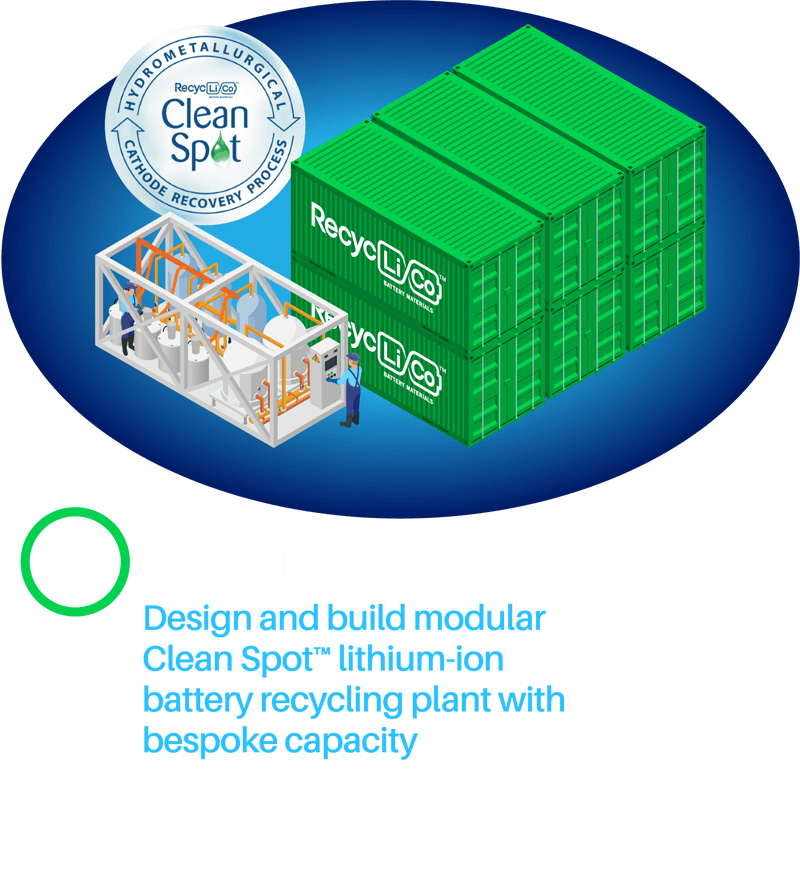

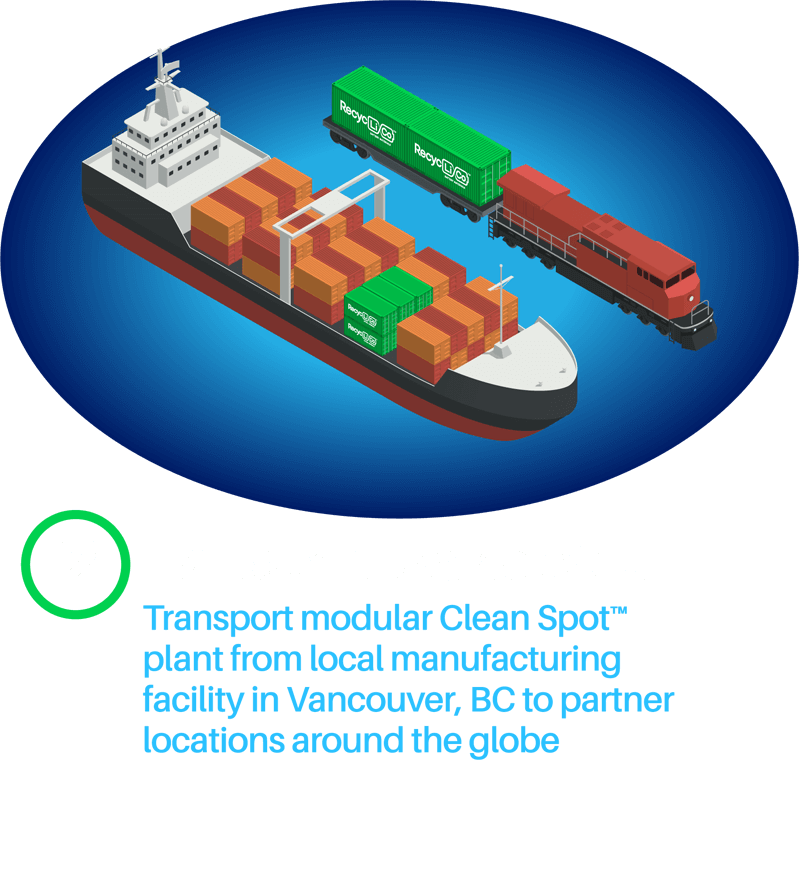

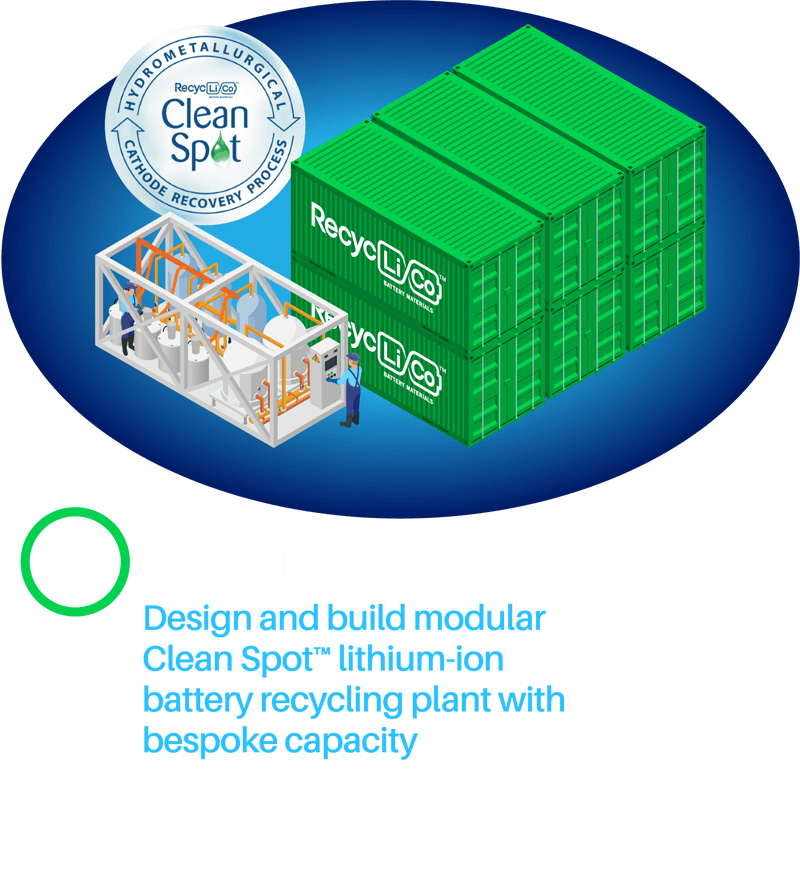

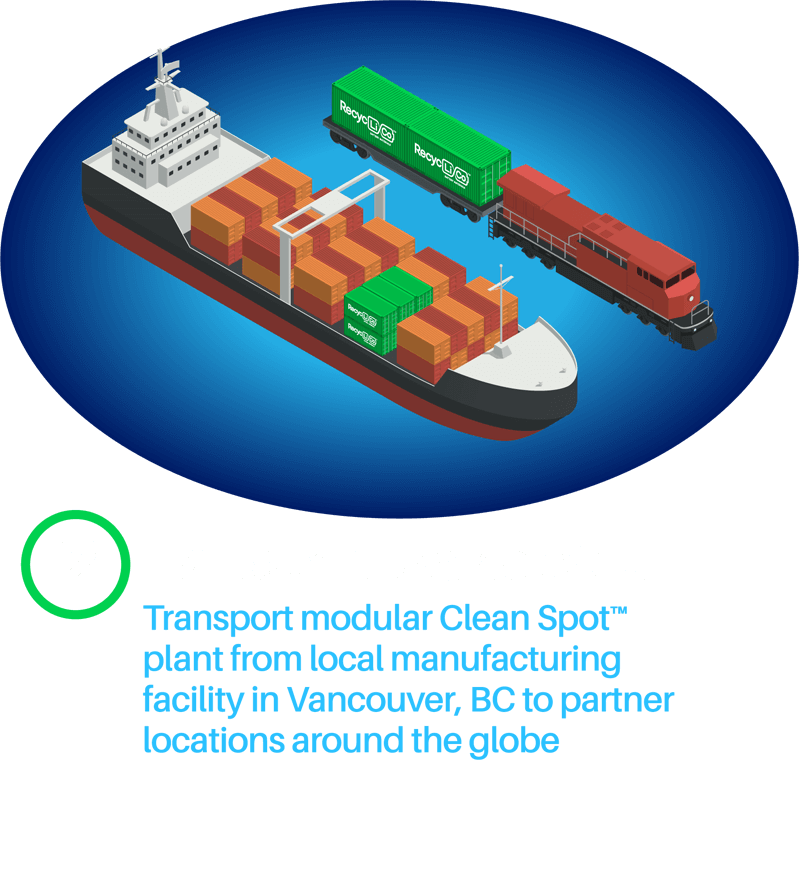

We Bring the Plant to You

Our Commercial Modular Plant Design Enables On-Site Battery Recycling Globally

We Bring the Plant to You

Our Commercial Modular Plant Design Enables On-Site Battery Recycling Globally

The World Needs the RecycLiCo™ Process

Our Unique Battery Recycling Technology Provides Multiple, Major Benefits

Fully Integrated Business Model

Recover up to 99% of the most valuable materials lost in current lithium-ion battery waste.

Sustainable Recycling Process

All battery-ready materials are 100% sourced from recycled lithium-ion batteries.

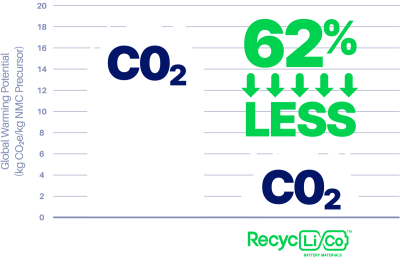

Independently Verified LCA

Life Cycle Assessment from Minviro reports 62% less CO2

than other battery recycling processes.*

Reduces Supply Chain Risk

Battery materials are vertically integrated and remain within control of the original facility.

Supports Stricter Regulations

Regulations requiring higher recycling efficiencies and recycled content continue to expand globally.

* In accordance with ISO-14040:2006 and ISO-14044:2006 standards.

Fully Integrated Business Model

Recover up to 99% of the most valuable materials lost in current lithium-ion battery waste.

Sustainable Recycling Process

All battery-ready materials are 100% sourced from recycled lithium-ion batteries.

Independently Verified LCA

Life Cycle Assessment from Minviro reports 62% less CO2

than other battery recycling processes.*

Reduces Supply Chain Risk

Battery materials are vertically integrated and remain within control of the original facility.

Supports Stricter Regulations

Regulations requiring higher recycling efficiencies and recycled content continue to expand globally.

* In accordance with ISO-14040:2006 and

ISO-14044:2006 standards.

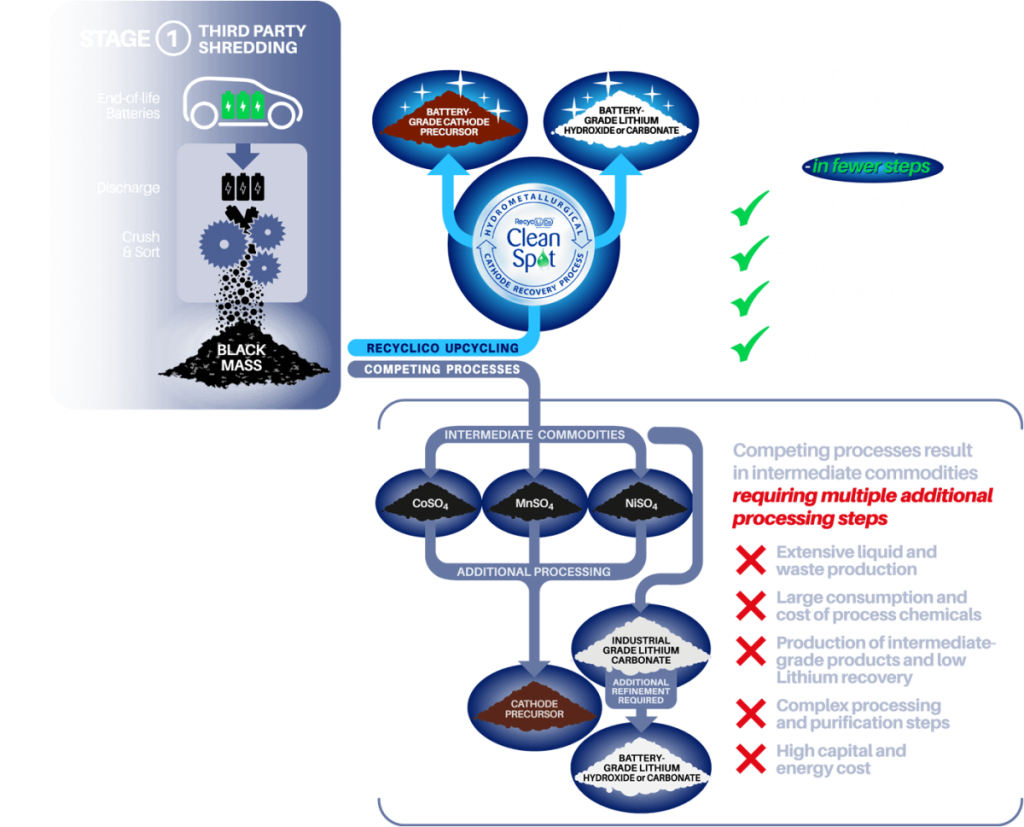

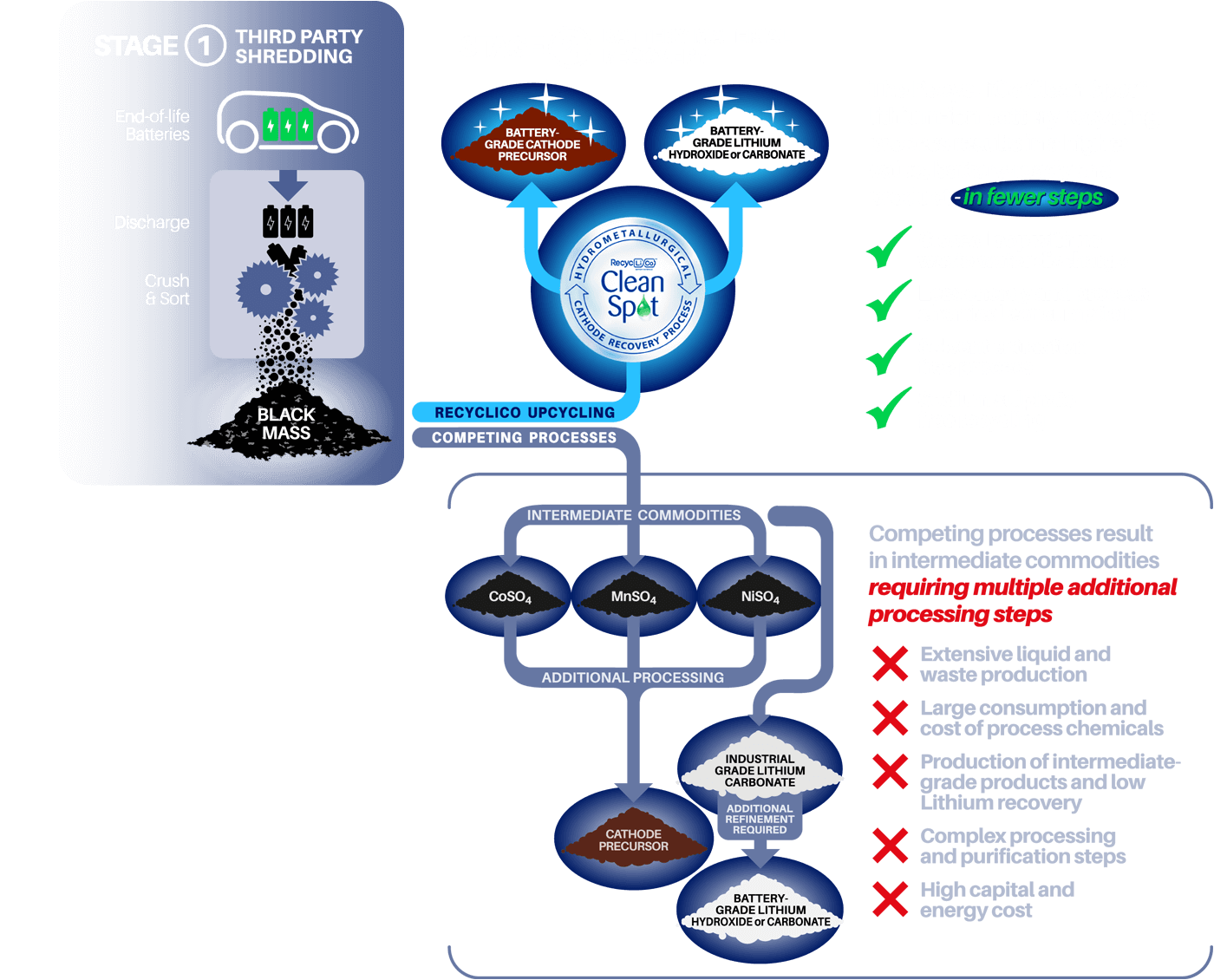

The RecycLiCo™ Process

Highly Adaptable, Modular & Energy Efficient

Beyond the clear benefits of integrating a modular, bespoke RecycLiCo Clean Spot™ plant, the core advantage is its high adaptability in the production of lithium and specifically engineered cathode precursor, while also eliminating multiple, energy intensive steps found in traditional lithium-ion battery recycling processes. All of which contributes to a much more efficient and sustainable circular economy.

The RecycLiCo™ Process

Highly Adaptable, Modular & Energy Efficient

Beyond the clear benefits of integrating a modular, bespoke RecycLiCo Clean Spot™ plant, the core advantage is its high adaptability in the production of lithium and specifically engineered cathode precursor, while also eliminating multiple, energy intensive steps found in traditional lithium-ion battery recycling processes. All of which contributes to a much more efficient and sustainable circular economy.

The RecycLiCo™ Process

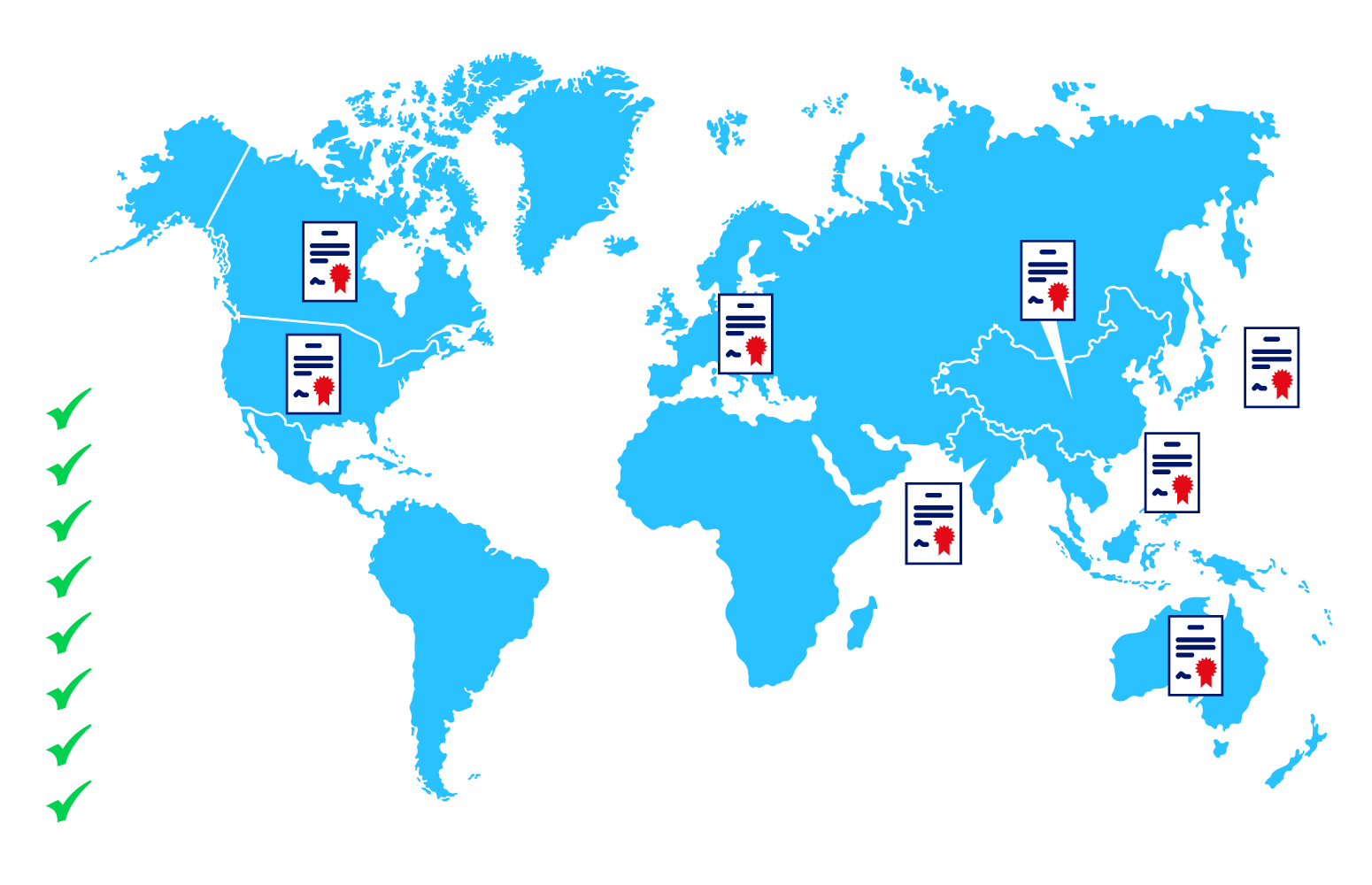

We have Patents Issued Around The World

The RecycLiCo™ Process

Need More Information?

Our team is ready to answer any questions you may have.

Our team is ready to answer any

questions you may have.